Woven straw fabric

Here is brief description of the three kinds of hats: how the hats are made and some of the main workforce, quality and style issues to know about. Plus a few insights into fitting and sizing hats.

Here is brief description of the three kinds of hats: how the hats are made and some of the main workforce, quality and style issues to know about. Plus a few insights into fitting and sizing hats.

Here is a Typical Scene of Women Working at a Table to Make Hats. Sewing is Often One Step in the Hat Making Process

Some Background on Hat Making . . . . covering three different types of hats

You should know about three kinds of hats.

The kinds of hats are:

1. Hand woven

2. Sewn from long ribbons or braids on a sewing machine

3. Sewn from stamped cutouts (including those sewn in sections from woven fabric).

Hand Woven

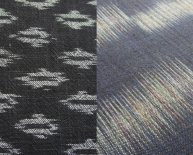

To the left you see a woman hand weaving a hat. Amazing as it seems, a great many hats are actually woven by hand. Those include hats most made from straw and raffia and crocheted hats. Look for the tightness of the weave and the quality of the material used. Note that some hats that appear to be hand woven may be stitched together from woven fabrics, including straw fabrics. Try distinguish those from others that are actually woven from scratch.

Sewn from Long Ribbons or Braids on a Sewing Machine

Sewn from Long Ribbons or Braids on a Sewing Machine

Below you can see a woman starting a paper braid (toyo) hat. It is the same as for a ribbon hat, except that the paper braid is more narrow. She starts with one end of the strand of braid and sews it in a tight circle with the machine. As she spins the hat around, she widens the hat in a ever growing circle. To shape the hat, she angles the braid tighter, creating a sharper curve. She will occasionally check the size by comparing the hat to a standard mold. Many of the hats you will buy are manufactured in this way. Look for careful sewing, good shape and care in how the material is tied off.

The paper braid she is using was actually made through a complex process by machine. First the colored paper, paper not dissimilar in feel to the kind of white tissue paper a high end department store might use to line a clothing box, is cut into thin strips. Then it is crushed into the shape of a string. The strings of paper are rolled onto spools and then braided by machine with cotton or polypropylene threads into the long braids used to make the hats. Below we will talk more about how paper braids are made.

Material Stamping Machine

Material Stamping Machine

The photo to the right shows a stamping machine that is stamping out felt (from made from fur) or polypropylene fabric to make fedoras. Each time the metal bar drops down it will press hard against cookie cutter type molds placed under it. They will cut the fabric into pieces that will then be sewn together to make the top, sides and rim of the hats.

After all the pieces are stamped out, then they are sewn together to make the hats. This woman is focusing on just one part of the hat, the part circling the head. Then she will pass off the work to someone else who will add another part of the hat. The one hat will go to several different people before it is finished. When you buy this kind of hat, look for the quality of the stitching at the seams. Check that the shape of the hat is even.

Hat Press

Hat Press

You may have noticed at the top of this lens a photo of what looks a little like a electric brain washing machine from a sci-fi movie. No worries, it is simply a hat press. After each hat is made, it will be pressed. Some of the hats will be dunked into a plastic like stiffer and left out to dry before being pressed. That way the hat will keep a stiff shape when it is worn.

There is really a lot more to know about how hats are made, but this hopefully gives you a little more insight into what you wear on your head or sell in your store!

Many Hats are made of Toyo. This is a kind of tissue paper that has been cut into long strips and folded or crushed to make a kind of thread. These threads are then woven together along with cotton threads or polypropylene threads (these look like fishing lines) to make a braid. The braid is what is used to make the hats. Sometimes the toyo is made into a twine instead of a braid for a different kind of look. If you go to see a paper braid factory you will really be amazed. What you find is not at all what you expect is being used to make hats. It is really a craft that will make your appreciate your hat materials (and your hats) a lot more.

In the photo above when the small rolls are just starting to go. They are blue and there are many all pushed together. After they are filled up about 6 inches high, the machine operator stops the machine, takes all the small rolls off and starts new rolls from the big sheet by using a little glue at the ends of the paper to hold onto the new small rolls. Sometimes these spools are sent out for further dyeing or printing after they have been cut.

Next, the paper on the spool is crushed to make a thread of paper as shown below,

These threads of tissue paper are then braided with threads of cotton or polypropylene to make the braid. How this is done precisely has a big effect on what the braid will look like. The machine below is weaving the braid from 9 strands of paper and 4 of cotton. Don’t try to count, since some of the threads you can’t see clearly in this photo because they are actually coming up from spools on the bottom front of the machine. The pink spool at the top is the finished braid. The white spools at the top are finished braids from other machines behind the pink braid machine. These machines all make an awfully loud noise!