May 21, 2018

Polyester melting temperature

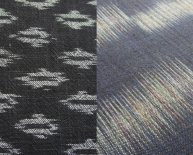

Should you be using a polypropylene or polyester sewing thread? We compare these two different materials to help you decide.

Should you be using a polypropylene or polyester sewing thread? We compare these two different materials to help you decide.

Polypropylene - Advantages:

- Lower specific gravity/density (0.91 g/cm³) – More fibers/unit weight (~25% more).

- More hydrophobic – absorbs less water and therefore dries faster.

- Lower heat transfer – Retains more heat.

- Inert to most chemicals.

Polypropylene – Disadvantages:

- Lower Melting Point 165 degrees C.

- Lower UV resistance – needs additives like Carbon Black to prevent rapid deterioration with UV exposure.

- Lower Strength – requires larger thread or yarn to meet strength targets.

- Lower creep resistance and higher elongation.

- Poor abrasion resistance.

- Not suitable for high speed sewing applications.

Polyester Advantages:

- Higher strength, tenacity and creep resistance – distinct advantage in Geotextiles and especially when load is on a fabric.

- Greater yield per pound.

- Higher melting point (260°C vs 165°C).

- Withstands high temperature washing and drying.

- More UV resistant - Retains strength and color better.

- Resistant to most chemicals.

- Has good flame resistance and flame retardant properties.

- Has good abrasion resistance.

- Polyester is used more for sewing – Higher strength and can withstand high temperatures generated during the sewing process (up to 350°C).

- Polyester produces a better all-around fabric and sewing thread.

Polyester Disadvantages:

- Higher specific gravity.

- Less hydrophobic, requires additives or coating to prevent wicking.

- Susceptible to damage if exposed to highly alkaline chemicals.