African Print stretch fabric

This comment inspired me to write a cheat sheet tutorial on how to know whether your fabric is napped or a one-way. If you’re a pro, don’t laugh, it’s not always so easy to know. Merrill gave me permission to quote (from the forum):

This comment inspired me to write a cheat sheet tutorial on how to know whether your fabric is napped or a one-way. If you’re a pro, don’t laugh, it’s not always so easy to know. Merrill gave me permission to quote (from the forum):

My company, RealKidz, has started using a new contractor, and when I went to visit I noticed that they were laying the pattern pieces far apart, the pieces were not locked in. I am concerned that they are wasting fabric and money! Has anyone else had this problem? When we asked the contractor they told us that because the fabric was a stretch twill in a solid color that this created a nap and that all the pieces had to be cut in the same direction from top to bottom. That there might be a difference in the shading of the color and that the fabric wouldn’t stretch on the body in the same way. Obviously it takes more fabric to cut like this and having never worked with stretch before, we wanted to make sure we are getting accurate information.

If you’re new to the site and new to sewing, nap usually refers to a raised pile or finish to a piece of fabric (or leather). This is most obvious in fabrics like velvet and corduroy. As you run your hand over the fabric, there is an obvious up and down direction to the pile. If you have not planned with pile in mind and your pieces are not cut in the same direction, the opposing sides of the finished product can look like different colors, just a shade or two off. We call this affect shading. We call a napped fabric a one-way because it can only be cut one way. The topic of cutting and laying fabrics (making markers) is quite involved so I can’t go into it but there’s a whole chapter on it in my book. In a nutshell, you have to know at the outset if your fabrics are a one way because they will cost more. For example, if you’re cutting a pair of pants out of denim and using the same pattern for corduroy, you’ll need more fabric for the corduroy than the denim. So even if the fabric costs the same per yard, the corduroy pant costs more to produce.

If you have not planned with pile in mind and your pieces are not cut in the same direction, the opposing sides of the finished product can look like different colors, just a shade or two off. We call this affect shading. We call a napped fabric a one-way because it can only be cut one way. The topic of cutting and laying fabrics (making markers) is quite involved so I can’t go into it but there’s a whole chapter on it in my book. In a nutshell, you have to know at the outset if your fabrics are a one way because they will cost more. For example, if you’re cutting a pair of pants out of denim and using the same pattern for corduroy, you’ll need more fabric for the corduroy than the denim. So even if the fabric costs the same per yard, the corduroy pant costs more to produce. It will cost more in fabric and marker costs because you can’t use the markers interchangeably.

It will cost more in fabric and marker costs because you can’t use the markers interchangeably.

As I said, Merrill’s question inspired me to write a cheat sheet to know if your goods are napped or one way. For this exercise I went to the fabric store and bought a twill denim (admittedly redundant). Being too lazy to search the aisles I first asked for corduroy which was a mistake because the clerk condescendingly informed me that corduroy was a winter fabric blah blah blah, explained all its properties (since I obviously couldn’t know what I was asking for, this being summer) but she never actually said they didn’t have any so you can imagine she wasn’t amused when I asked again if they had any. Literal thinking, that. She deserved it. Anyway, here’s how I set up a test and how you should too.

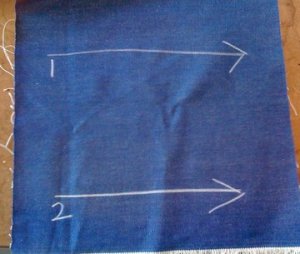

Below I’ve marked two arrows on the fabric. You don’t have to number them, I just thought I would in case it were important later.

Below you’ll see I’ve cut them apart in rectangles and then turned them around so the arrows run opposite to each other and then sewed them back together.

At this stage it is usually easy to tell if a garment is shaded. One side will look slightly different in color. This denim sample above looked just fine.

In the course of this experiment, I discovered something very interesting. You should photograph your test results. The reason is illustrated in this next example of a stretch velvet (below).

The velvet fabric laid flat above looked pretty good to the eye in real life but it didn’t fool the camera. I don’t know enough about the hows and whys of photography to know how this happened but obviously the camera caught light glinting off the pile and darkened/lightened each side accordingly. So, that is a lesson you don’t have to learn the expensive hard way, photograph your samples!

So, that is a lesson you don’t have to learn the expensive hard way, photograph your samples!

The camera doesn’t catch everything though. This next sample below is of black rayon velvet. When the two sides were put together in real life, one side looked slightly, just ever so slightly, greyer than the other. If I’d pressed this sample, you’d get the full effect, the two sides look the same color. Yet another reason I say to not cut your protos in black or very dark colors.

Of course nap is not the only problem you can have, there’s other kinds of one-ways such as prints. A lot of fabrics used in high end ladies pajamas have a print that only runs in one direction (in case you wondered why they were so expensive). Below is an example of an embroidered Guatemalan fabric:

If you cut and sew a sample, laying the pieces opposite to each other, you’ll see it doesn’t quite match (below). I still think this is a nice piece, its maker went to a great deal of trouble to create a repeat that would match so it wouldn’t be a one way but they forgot to alternate the up/down (but not side to side) orientation of the animals.