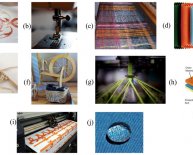

Types of textile industry in India

Significant financial saving and environmental improvements can be made by relatively low-cost and straightforward interventions in the textile industry, and this improves the quality of products and minimises the cost of production, say C Parvathi, T Maruthavanan and C Prakash.

Textile processing industry is characterised not only by the large volume of water required for various unit operations but also by the variety of chemicals used for various processes. There is a long sequence of wet processing stages requiring inputs of water, chemical and energy and generating wastes at each stage. The other feature of this industry, which is a backbone of fashion garment, is large variation in demand of type, pattern and colour combination of fabric resulting into significant fluctuation in waste generation volume and load. Textile processing generates many waste streams, including liquid, gaseous and solid wastes, some of which may be hazardous. The nature of the waste generated depends on the type of textile facility, the processes and technologies being operated, and the types of fibres and chemicals used. The overview on the amounts of waste generated within the textile processes are summarised in Table 1.

Textile industry overview

The textile industry is a significant contributor to many national economies, encompassing both small and large-scale operations worldwide. In terms of its output or production and employment, the textile industry is one of the largest industries in the world.

The textile manufacturing process is characterised by the high consumption of resources like water, fuel and a variety of chemicals in a long process sequence that generates a significant amount of waste. The common practices of low process efficiency result in substantial wastage of resources and a severe...