Viscose natural or synthetic

Viscose or more commonly known as Rayon, was made to substitute for the more expensive silk fiber. Though rayon is considered to be synthetic it is made from tree cellulose. It was first manufactured by an American Company named, Avtex Fibers Inc in 1910. There are different kinds of rayons, and most of them are highly absorbent, easy to dye, soft on the skin and became very popular when it was first produced.

How is Rayon processed?

- Viscose is manufactured by treating purified cellulose in caustic soda solution to form a salt of soda cellulose.

- The white crumb is then exposed under controlled conditions to oxygen so as to oxidize it. This involves careful monitoring so that the length of the fibers is short enough to manage the viscosity of the solution but long enough to produce good fibers.

- The soda cellulose aged fiber is then treated with carbon disulphide, CS2. This results in formation of xanthate esters plus some inorganic impurities which gives the fibers a yellow color and from her eon called as yellow crumb.

- After ripening and filtering, degassing is done to remove any air bubbles in the fabric,

- stretching is done to draw it into filaments and textile fabrics.

- It is washed using several techniques

Applications of viscose

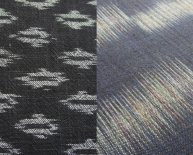

Viscose is soft, absorbent and feels comfortable when worn on the skin. Viscose is used in the preparation of shirts, trousers, diapers, napkins, towels and many other products. Viscous fiber material is present in many home products. Viscose material is softer than cotton and more springy than silk. Viscose is comfortable to wear and it can be used for dying as well. There are two types of fibers namely natural and artificial. Natural fibers are cotton, wool and silk and artificial are synthesized with petrochemicals like nylon and polyester.