Methods of Textile printing

Paisleys and polka dots, flowers and stripes! Have you ever wondered how those fabulous, colorful images end up on fabric? In this lesson, explore some of the methods and tools used in textile printing.

Paisleys and polka dots, flowers and stripes! Have you ever wondered how those fabulous, colorful images end up on fabric? In this lesson, explore some of the methods and tools used in textile printing.

Introduction

Humans have worn colorful, printed textiles for thousands of years. There are many ways to print designs on fabric, and in this lesson we're going to explore a few of them. But first, you should know that all of the printing methods we will discuss require a few first steps before printing takes place. If the fabric is not going to remain its natural color, it must be dyed an overall shade. All fabrics have to be pretreated before the printing process - the specifics depend on the type of process being used. Now, let's look at the three main categories of how printing on textiles is done and some of the tools needed.

Direct Printing

The first is direct printing, where color ink pastes are imprinted onto a fabric. This is the most straightforward method of textile printing. Examples of direct printing include block printing and roller printing.

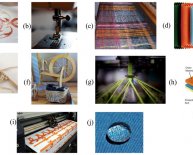

Example of a woman block printing fabric. The textile has been dyed blue, and the ink used on the block print is white.Block printing is one of the oldest methods used for textile printing, and we can find examples from hundreds of years ago. A design is carved onto a wooden or metal block. That block is dipped in dye paste and pressed onto the fabric's surface. It's simple and can be done with just a few tools, but this process is time-consuming and is done by hand. Roller printing, developed in England in the 1780s, allows the process to be mechanized. A design is engraved onto a copper cylinder or roller. When it's rolled over the fabric, it prints the design, repeating it with every complete roll. This method is continuous and can print great quantities of fabric. Both methods can be used to produce colorful, intricate patterns.

Discharge Printing

Another method of textile printing is discharge printing, a process that uses a water-based ink to deactivate or destroy the color dye in a fabric. This method is also sometimes called extract printing. In discharge printing methods, the ink is clear and contains a substance called an activator. When it's printed onto fabric, the inked areas turn a lighter color and look like they have been bleached. Color can also be added to the discharge ink so the lightened areas can include more than just one lighter tone. One method used to apply discharged inks is screen printing, where a stencil is applied to a mesh screen. Ink is then pushed through the screen so that the stencil image is printed onto the fabric. The process is repeated with separate screens for each desired color.

Unlock Content

Over 30, 000 lessons in all major subjectsGet FREE access for 5 days,

just create an account.

No obligation, cancel anytime.

Want to learn more?Select a subject to preview related courses:

Resist Printing

Resist printing involves a substance like melted wax or specific chemicals called a resist that are applied to fabric to prevent color from sticking. Resist printing can be done with many tools, including rollers or blocks. In either case, a design is applied using the resist substance and allowed to dry. Then, colored dye that won't stick to the resist is applied. In areas of the pattern covered by resist, the underlying color shows through. In intricate patterns, this process of applying resist then dye is repeated until the desired layers are reached. One type of printing that uses this process, batik, has been practiced for centuries in Indonesia and other parts of Asia. Although sometimes prints done with resist and discharge methods look similar, an advantage of resist printing is that it can produce designs with high colorfastness due to dye specifics and the use of resists rather than discharge inks.

Example of resist printing wheels.So, now you know more about different textile printing methods and some of the needed tools. The next time you buy a new outfit or happen to be around bright and bold fabrics, look closely at them. Can you identify which method was used to print them? Perhaps you could try to print your own!

Lesson Summary

People use many methods to print colorful designs on textiles. The three main categories are direct printing, in which dye is applied in a pattern to fabric; discharge printing, also known as extract printing, in which clear ink with an activator bleaches a pattern into an already dyed fabric; and resist printing, in which liquid wax or another chemical substance called a resist is first applied to fabric. When the resist dries, ink is applied and doesn't stick in the areas with the resist. Batik is one kind of resist printing. Common printing processes that can be used with one or more of these methods include block printing, roller printing and screen printing.